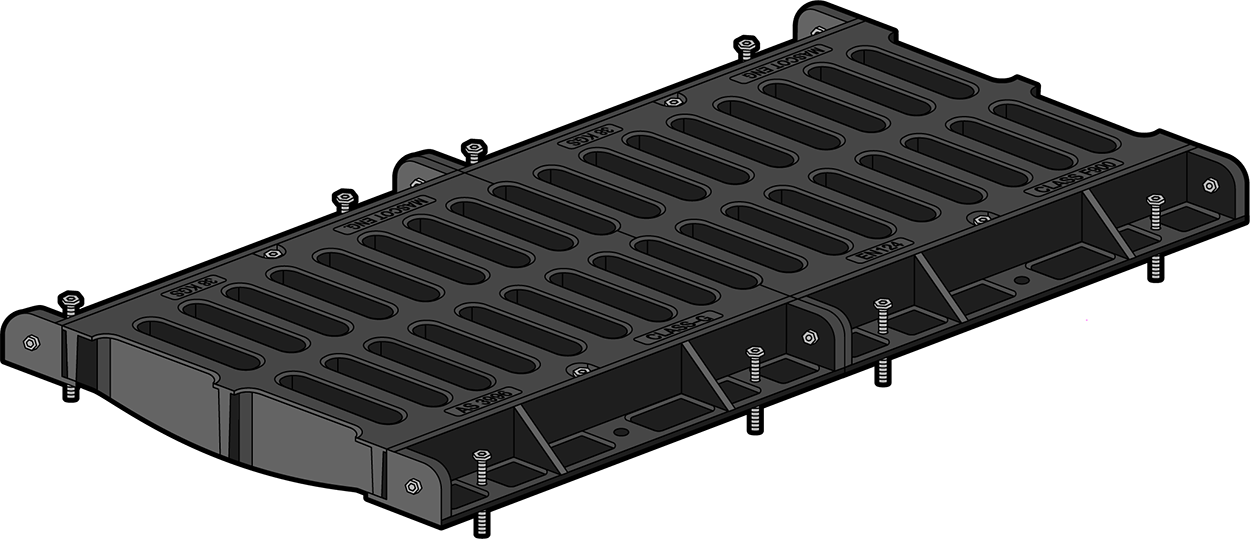

Trench Grating

The Original. Mascot Engineering is one of Australia’s original manufacturers of iron trench grating, with a history dating back to 1920. Our first iron foundry opened near Sydney Airport, and many of our original drainage grates are still in service across Sydney’s streets today. More than 100 years later, Mascot trench grates are trusted on infrastructure projects around the world, delivering durability, safety, and performance.

We manufacture and stock a wide range of trench drainage grating for managing stormwater and surface runoff. Our grates are engineered and tested to meet EN 1433 and EN 124-2 load ratings from Class C250 to Class F900, making them suitable for everything from pedestrian areas to heavy-duty industrial and transport applications such as Airports and Ports.

Trench Grating Features

-

Secure Boltdown Options – Keeps trench grates locked in place, ensuring safety in high-traffic areas

-

Slip-Resistant Surface – Improves pedestrian and worker safety in wet or oily conditions

-

Non-Rocking Design – Precision fit eliminates rattle, movement, and noise

-

Integrated Levelling Bolts – Speeds up installation and ensures accurate, level placement

-

Fire System Compatibility – Designed to work with fire suppression systems

-

Versatile Applications – Ideal for stormwater drainage, trade waste, and surface runoff

-

Design Flexibility – Available in multiple styles, patterns, and heelproof grating options

-

Hydraulic Efficiency – Maximises flow capacity with a range of opening sizes

With a century of experience, Mascot Engineering trench grating is the proven choice for councils, civil contractors, builders, and engineers who demand reliable drainage solutions that look great and perform under pressure.

The Range

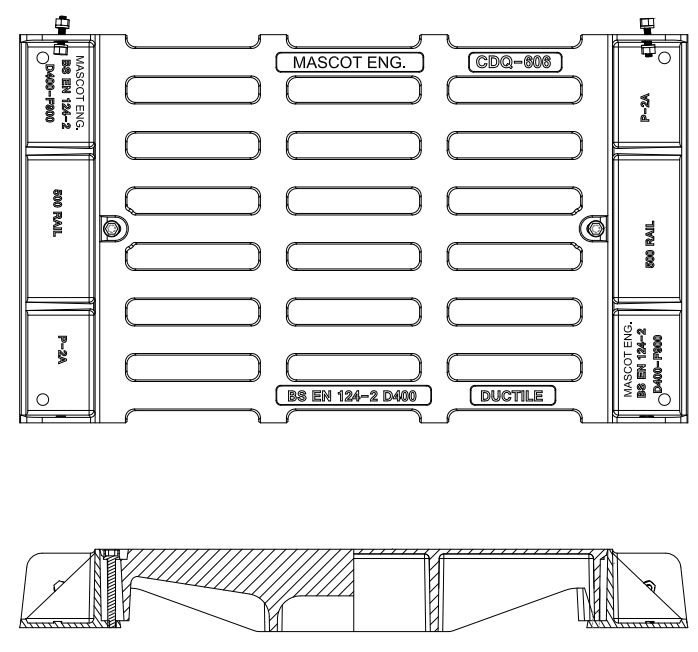

Mascot Engineering’s Cast Iron Grate and Frames are available in either standard lengths, or custom sizes can be arranged to suit the specific requirements of your project. Grates are fitted standard with lockdown points and frames are fitted with Mascot’s patented levelling system to ease installation.

| Clear Opening | Length | C250 | D400 | E600 | F900 |

|---|---|---|---|---|---|

| 300 | 500 | EN-TG300C | EN-TG300D | EN-TG300E | EN-TG300F |

| 450 | 500 | EN-TG450C | EN-TG450D | EN-TG450E | EN-TG450F |

| 600 | 500 | EN-TG600C | EN-TG600D | EN-TG600E | EN-TG600F |

| 750 | 500 | EN-TG750C | EN-TG750D | EN-TG750E | EN-TG750F |

| 800 | 500 | EN-TG800C | EN-TG800D | EN-TG800E | EN-TG800F |

| 900 | 500 | EN-TG900C | EN-TG900D | EN-TG900E | EN-TG900F |

| 1000 | 300 | EN-TG1000C | EN-TG1000D | EN-TG1000E | EN-TG1000F |

| 1200 | 300 | EN-TG1200C | EN-TG1200D | EN-TG1200E | EN-TG1200F |

| 1500 | 300 | EN-TG1500C | EN-TG1500D | EN-TG1500E | EN-TG1500F |

Note: Grate and Frames are priced in 1m lengths.

Custom Grating – Designed for your project

With an in-house product development team and a commitment to innovation, we will work with you from concept, through manufacture and delivery of a grating system to suit your project requirements. To discuss your requirements, contact us at sales@mascotengineering.com

Standards & Testing

Mascot Engineering’s cast and ductile iron products are manufactured in a foundry that is ISO9001 accredited and all covers go through a rigorous quality assurance program and manufactured to load ratings set out in EN124-2 and EN 1433.

Our in-house technical team and third party certified testing facility ensures product compliance and gives you peace of mind.

In addition to quality, our foundry is also third party accredited to ISO 140001. This standard recognises the environmental management system that’s in place – protecting the environment whilst operating sustainably for future generations.